Past cases

Commercial Vessel Incidents

We specialize in conducting comprehensive forensic investigations into commercial vessel incidents, such as stranding, grounding, sinking, collisions, allisions, capsizing/listing, propulsion and machinery failures, fire and explosion events, cargo damage, and pollution incidents.

Our approach involves meticulous evidence collection, thorough data analysis (for example, VDR data review and examination, met-Ocean data analysis) and the application of cutting-edge investigative techniques. We provide expert opinions on the root causes, contributing factors, and liability assessment related to commercial vessel incidents.

Whether serving as an expert witness in litigation and arbitration proceedings or delivering assessments for insurance claims, we aim to facilitate informed decision-making and contribute to the fair resolution of commercial vessel incident disputes.

Cases resolved in UK(LMAA), Singapore, Denmark

Onshore Structural Failures

We investigate onshore structural failures, including large steel structures, cranes, towers, and more. Backed by extensive experience and technical expertise, we conduct thorough examinations to uncover the root causes of these failures.

We work with multidisciplined team of experts such as metallurgists, geologists, and civil engineers, employs advanced analytical and numerical tools to assess factors such as design flaws, construction quality, material deficiencies, environmental conditions, and operational stresses. By combining meticulous site inspections, laboratory testing, and computer modeling, we provide clients with a comprehensive understanding of failure mechanisms.

Whether for insurance claims, legal disputes, or engineering design and preventive measures, we deliver actionable insights and expert opinions to help clients make informed decisions, mitigate risks, and reduce remedial costs.

Cases resolved in UK(LMAA), Singapore, Hong Kong

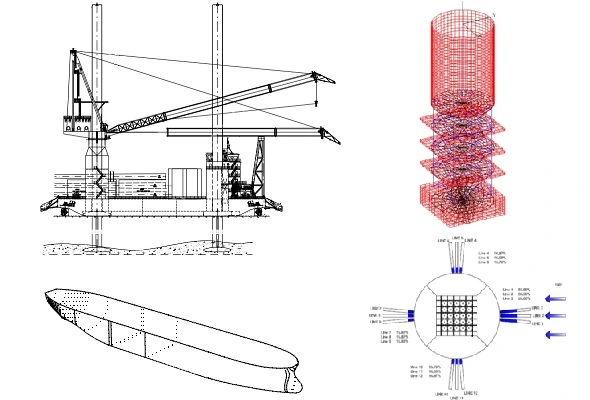

Design Defects

Despite ongoing improvements in shipbuilding rules, standards, and the adoption of new technologies, maritime accidents continue to occur due to inadequate design. We have been actively involved in helping ship owners, designers, and shipyards in identifying design defects and assessing potential corrective measures.

In recent times, we have assisted many design disputes regarding offshore wind turbine installation/service vessels. The design of these types of vessels are more challenging and error prone due to their distinctive feature of high-outreach cranes on the deck, and the less established design rules and standards governing them.

Cases resolved in UK, Hong Kong and China

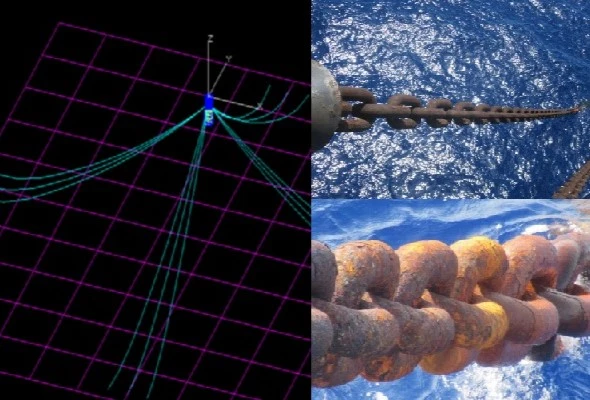

Subsea Damages (Mooring, pipeline erosion)

Subsea structures such as mooring lines, risers, and pipelines face the constant threat of damage due to their exposure to corrosive marine environments and the ever-changing loads due to environmental changes, operational demands, and unforeseen impact forces.

We have advised on a range of disputes related to mooring chain or cable failures. The root causes of these failures can be diverse, including design inaccuracies, installation errors, faulty materials and inadequate maintenance. Furthermore, we have developed our in-house mooring analysis tool and CFD code to accurately simulate and analyze the adequacy and efficiency of mooring designs.

Cases resolved in Singapore, New Zealand and China

Ship Performance and Fuel Consumption

As is commonly acknowledged, ship speed performance and fuel oil consumption stand as pivotal considerations for ship owners and charter parties, driven by both economic and ecological concerns.

Ship owners are actively undertaking fleet upgrades to align with the recently implemented CO2 emission requirements, specifically those outlined in IMO’s MEPC 76. These regulations encompass essential measures targeting the reduction of CO2 emissions for both existing vessels (EEXI) and newly designed ships (EEDI).

Our involvement in this context has included extensive support to numerous ship owners in assessing their vessels’ performance, evaluating the effectiveness of emerging technologies such as air lubrication systems and propulsion energy-saving devices, and providing expert insights into the overall efficiency of their propulsion systems. Moreover, we have provided expert evidence in disputes related to new builds and Charter Party.

Cases resolved in UK(LMAA), Singapore, Hong Kong

Fatigue Analysis

Moving components on marine vessels and offshore structures are susceptible to vibration and fatigue-related damages, with some of these issues arising from subpar workmanship, inadequate corrosion protection or welding defects.

Our expertise has been applied to investigate numerous incidents involving propeller vibrations, turbocharger vibrations and associated damages, gearbox fatigue failures, thruster noise and vibrations, as well as bearing fatigue failures.

In the majority of these fatigue analyses, we have conducted Finite Element Method (FEM) calculations to evaluate the initial design and calculations, and subsequently comparing them to in-situ measurements. Our efforts have consistently proven beneficial in assisting clients in resolving their disputes through mediation, arbitration, or court proceedings, demonstrating our capacity to deliver effective solutions in these complex matters.